| Specification | Details |

|---|---|

| Material Used | Stainless Steel, Mild Steel with Powder Coating |

| Machine Types | Manual, Semi-Automatic, Fully Automatic |

| Sealing Methods | Heat Sealing, Induction Sealing, Vacuum Sealing, Ultrasonic Sealing |

| Sealing Speed | 10 - 100 packs per minute (Varies by Model) |

| Power Consumption | 220V/50Hz (Custom Voltage Available) |

| Control System | Digital Temperature Control, Touch Panel, PLC Control |

| Benefits | High Efficiency, Leakproof Sealing, Durable, Energy-Efficient |

| Usage Applications | Food Packaging, Pharmaceuticals, Beverages, Industrial Packaging |

| Customization | Size, Power, Speed, and Branding Options Available. |

| Quality Certification | ISO, CE, GMP Certified. |

The sealing machine for packaging is arguably the most important tool in a wide variety of industries by ensuring the safety of products, the longevity of products, and better packaging quality. Food, pharmaceuticals, cosmetics, and manufacturing industries use these packaging machines for the assurance of security as well as airtight packaging. The investment in a good sealing machine for packaging greatly increases productivity, lowers wastage in operation, and makes the enterprise comply with industry standards.

Up to recent advancements, modern sealing machines for packaging are noted for speed, precision, and flexibility in speed. If heat sealing, vacuum sealing, or induction sealing is all you want, then there is a large variety of such machines that can satisfy even those in the specific needs of industry.

Heat Sealers :Heat sealers function mostly by using the application of heat and pressure in generating a perfect seal in sealing materials. These machines are common mainly in the field of making plastic bags, pouches, and laminates in the food and pharmaceutical industries.

Vacuum Sealing Machines :These machines evacuate the air from the packaging before its sealing. That is, they prevent oxygen exposure, bacterial growth, and spoilage of contents. Vacuum sealing is mostly used with perishable food items and medical supplies.

Induction Sealing Machines :An induction sealer binds a foil seal to the rim of the container with electromagnetic waves. This procedure is popularly used in the pharmaceutical and beverage industries in making tamper-proof packages.

Band Sealing Machines :It's the same sealing application continuously for high-speed operations. Those businesses that demand a fast and efficient sealing technique, for example, food packaging and e-commerce, can benefit most from it.

Impulse Sealing Machines :Impulse sealers operate using a brief pulse of electricity which creates a heat-sealed bond. These machines are often used in sealing polyethylene and polypropylene bags.

Ultrasonic Sealing Machines :A very high-frequency sound wave generates heat to create a very durable, airtight contact. Used in medical and specialty packaging.

Enhanced Product Safety and Hygiene :A packaging sealing machine guarantees airtight seals that secure the products from contaminants, dust, and moisture, ideally ensuring freshness and hygiene.

Increased Efficiency and Production :Sealing machines automate sealing operations; hence, they reduce the amount of manual work involved, thereby increasing and optimizing production efficiency and saving labor costs.

Shelf Life Promotion :Excellent sealing ensures that the products will not be exposed to air, oxidation, or spoilage, increasing shelf life.

Cent percent Packaging Reliability :Sealing machines provide packing consistency, avoiding human error and giving the final product a good appearance.

Adaptability for Packaging Materials :Today's sealing machines accommodate several packaging materials: plastic, aluminum, paper, and laminated films.

Regulation Compliance :With a good sealing machine, companies can meet regulations stipulated for packaging, which effectively guarantees product safety and earns consumer confidence.

In selecting a sealing machines for packaging, the kind of packaging material, sealing technology (be it heat, vacuum, or ultrasonic), and speed of production should be thoroughly considered. The level of automation, either manual, semi-automatic or fully automatic, should further match operational needs. Durability and low maintenance ensure long-term operational efficiency. When the correct machine is selected, the productivity of the business will increase while product safety and cost savings are maintained.

Food Industry :Snacks, dairy products, frozen foods, and ready-to-eat meals are packaged using this machine.

Pharmaceutical Sector :Provides tamper-proof packaging of medicines and medical supplies.

Cosmetics Sector :Seals skincare and personal care products against contamination.

E-commerce and Retail :Provides security for online orders and merchandise bought in stores.

We specialize in offering various sealing machines for packaging which include durability, efficiency, and precision. With machines designed for several industries, we offer advanced sealing technology for airtight and secure packaging. Promising quality coupled with innovative technology, Polypack Enterprises is committed to developing efficient and cost-effective, yet user-friendly solutions to cover all diverse packaging needs.

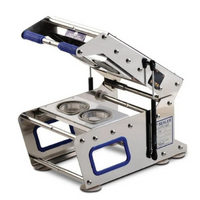

Efficient and reliable round sealing machine for precise sealing of containers. Ideal for various industries, ensuring airtight, leak-proof seals with ease. Contact us today!

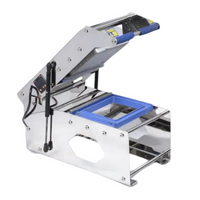

Efficient Rectangle Sealing Machine for precise packaging. Ideal for sealing various materials, ensuring airtight and secure seals. Perfect for industrial and commercial use.

Efficient Tray Sealing Machine for food packaging, ensuring airtight seals to extend freshness. Ideal for various tray sizes with easy-to-use controls. Enhance your packaging now!